NO PROBLEM

We are proud of the ongoing relationships we have with many of our customers. We provide honest advice and deliver appropriate solutions. Below is a selection of testimonials from some of our customers. Please contact us to find out more.

Renishaw

Renishaw has a long history with Human Workspace and have purchased over 2,000 workstations over the years. They trust us to provide advice and deliver appropriate solutions.

“One of the things I like about their kit is that it can be reconfigured very quickly and flexibly so we can maximise the use of our space – it’s like Engineers Meccano.

I also value their expertise in problem-solving, for instance, we had a problem with damage to an expensive component and, after a conversation, they suggested a storage system which has completely eradicated the problem and the expense.

The fact that they can take projects from our early-stage 2D layouts and take over design, procurement and installation is very important. On large-scale projects it is simply not effective of our time and we fully trust them to deliver what we need.”

De Soutter Medical

De Soutter Medical is a leading European manufacturer of surgical power tools. They built a purpose-built factory with the help of Human Workspace.

“Human Workspace understand our business and how lean initiatives are important when it comes to manufacturing in a competitive market. They take an engineering approach to find a solution that works for our operation and output. Ultimately, we measure their worth in efficiency gains and this is in evidence across all production. In one production cell alone, the Human Workspace solution increased output from 15 hand pieces per 10 days to 30.

In our experience, Human Workspace delivers a premium product and solution every time. They also appreciate that a growing business needs the flexibility to expand and evolve the manufacturing process so we will be delighted to work with them as we expand our operations in the future.”

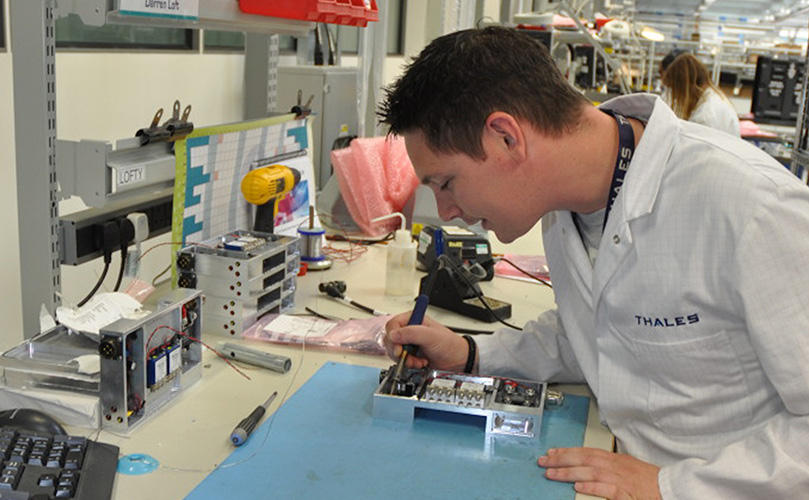

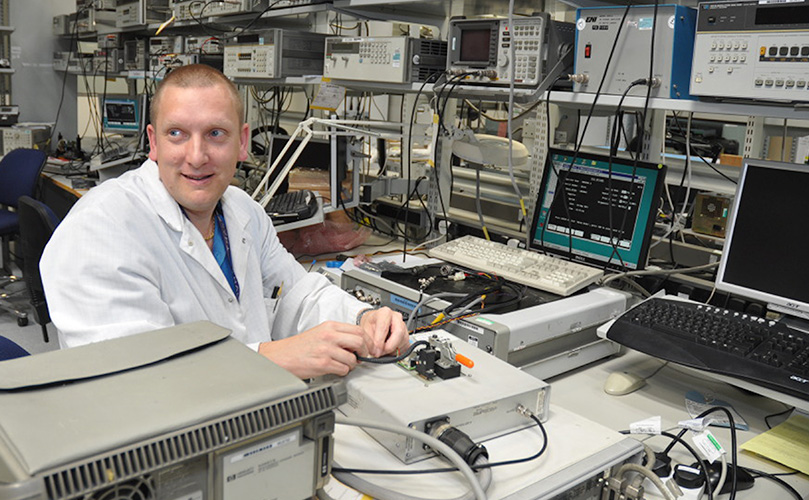

The Thales Group

The Thales Group is one of the largest defence contractors in the world, with over 68,000 employees in more than 50 countries around the world. Thales doesn’t just specialise in defence though: in the UK, it provides equipment for the banking, finance, energy and air travel sectors as well.

The company’s showcase manufacturing site in the UK is in Crawley, England, where over 2,500 people are based. The facility focuses on testing, developing and supplying a variety of high technology civil, military and security equipment.

“The work of Thales’s 2,500 employees in Crawley is crucial to Britain’s front-line troops,” Laura Moffatt, the Member of Parliament for Crawley remarked after a recent tour of the site. “I believe our troops are as well equipped for their own personal protection and for engaging in fighting as any in the world.”

On the factory floor, the emphasis is on flexibility and adaptability. “Flexibility is absolutely key,” James Grover, Production Manager, says. “We have to be able to change the configuration of the factory floor in 24 hours, so that we can respond to our customers’ needs. If we don’t change, then everyone will change around us and we’ll lose our position in the market: so efficiency and speed of change is very important.”

Thales has been using HWS workspaces for over four years. “We’ve never had a problem,” James states. “The benches are easy. They’re light, you can put them onto skates and just wheel them around. Everything on the shop floor is designed to be fully flexible, so we can just plug and go: it really is as simple as that.”

As well as being flexible, the benches are also adaptable to individual needs. “Some of the guys don’t like the swinging arms, and the swinging bins. Some of them do,” James continues. “Some of them are gadget freaks and the more bits they can fit on them the better. Some of the guys like the lights up above them, some like them lower down: it depends on what they’re doing. It really means they can be set up according to personal choice.”

Thales don’t just use the benches: they also benefit from the strategic expertise at HWS, so they can configure each factory floor area to maximise its use. “Prices are at a premium here, and we can’t afford dead space,” James adds. “HWS are critical in helping us to design the layout we need: you can’t put a price on that.”

“HWS are very responsive: we can ring them up,” James says, “and they’ll know what we need to be doing before they get here. It’s helping us to achieve our aims in making the factory space as lean as possible.”